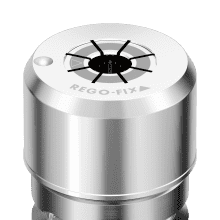

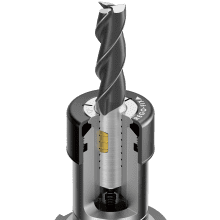

Discover our sales network

Our global network is one of the key factors of our leadership position and a promise to deliver innovative toolholding solutions and excellent service close to you.